China OEM Inverter Fan & Electric Fan Manufacturer

Guangdong Shunde Bafeier Electric Appliance Technology Co., Ltd. is a manufacturing enterprise that focuses on production and development of high technology smart appliances, primarily with household floor fans, commercial, industrial and ventilation fans.

With a quality oriented attitude, electric fan supplier innovative and pragmatic spirit of research and development within the Research and Development team our company has successfully developed and patented a DC (Direct Currency) motor fan to be an industry leader. What makes this DC motor unique is it is more energy efficient, low noise, smooth operation which allows electric fan supplier Bafeier products to last longer than other electric fans.

read more about bafeierHot Inverter Fan Products

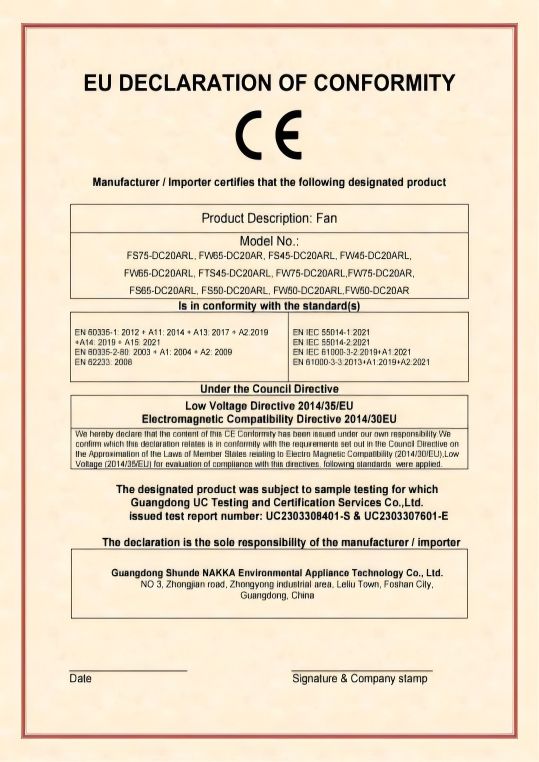

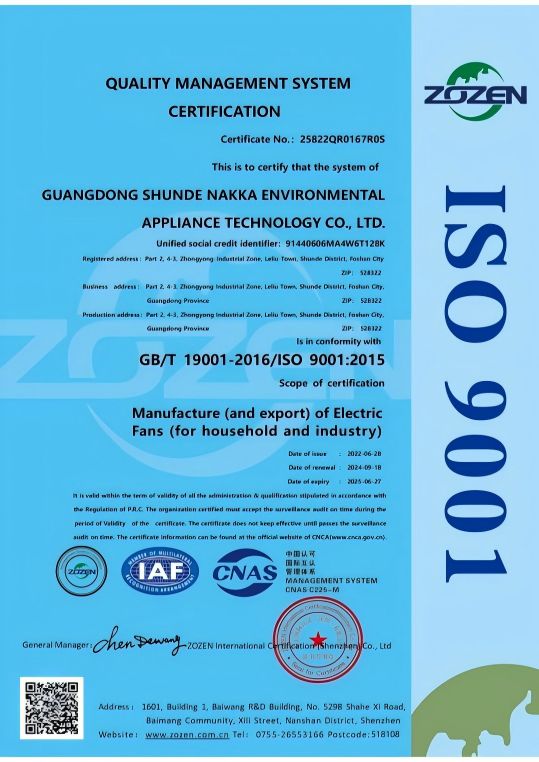

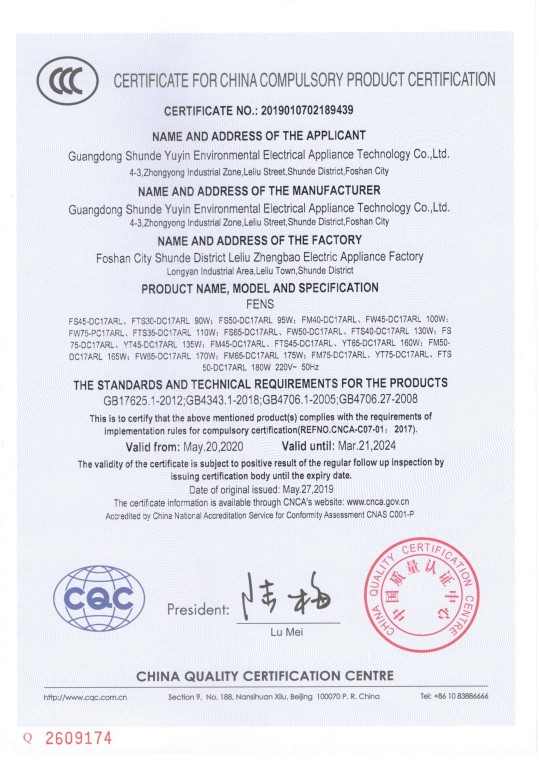

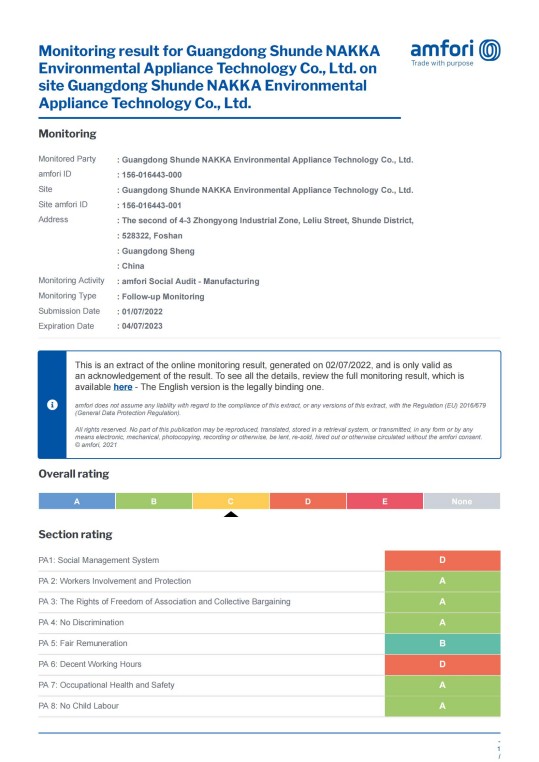

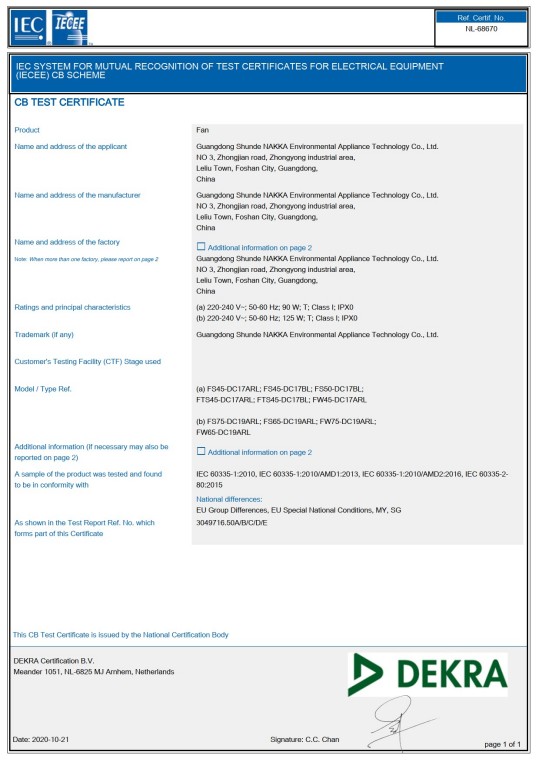

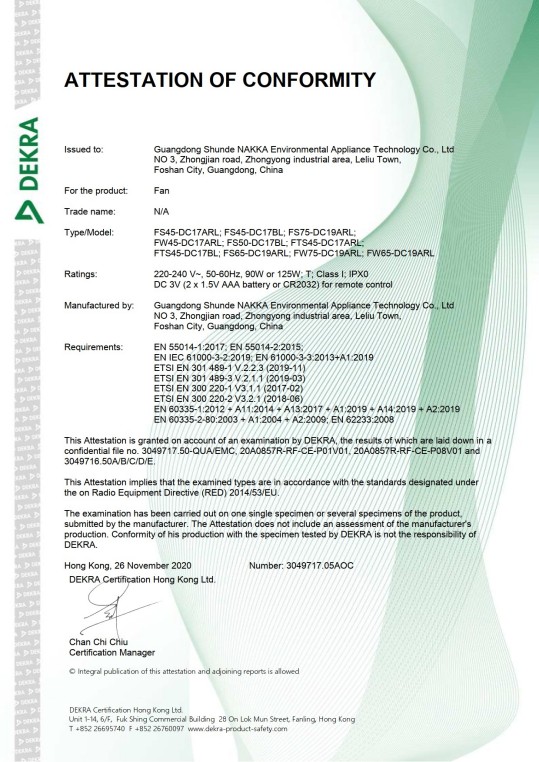

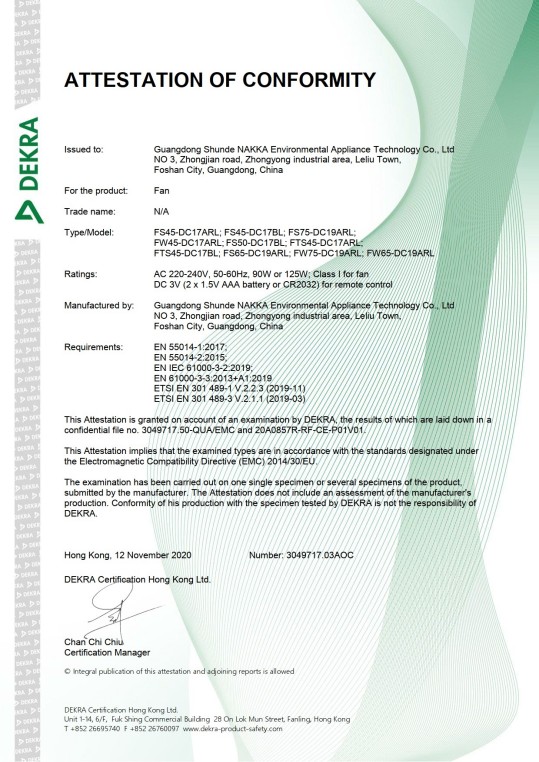

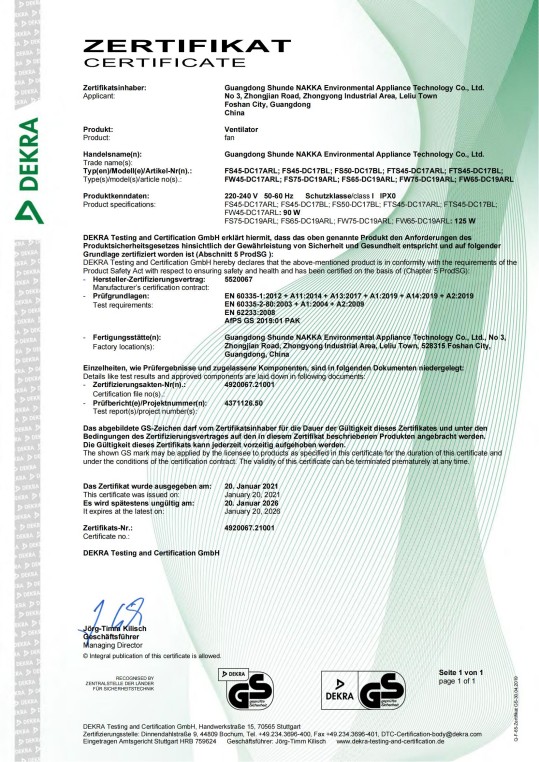

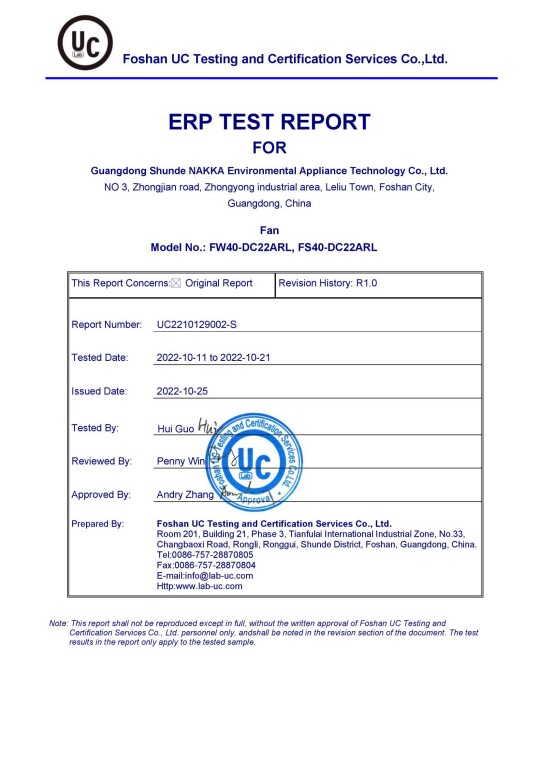

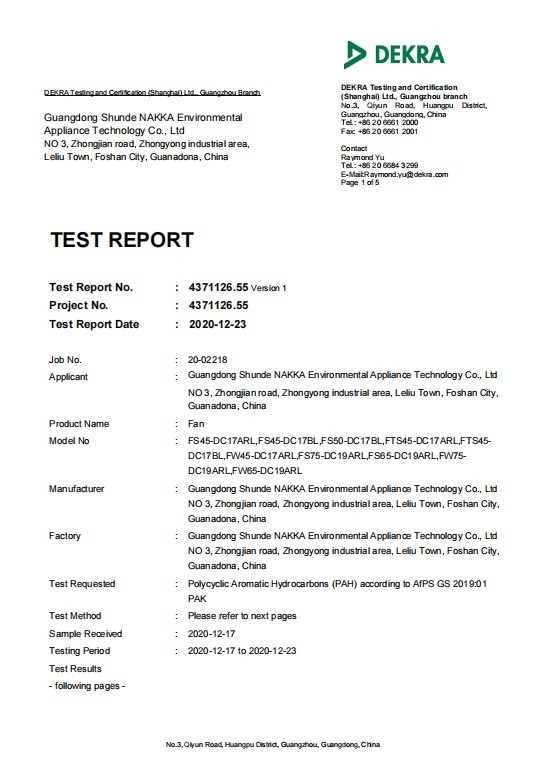

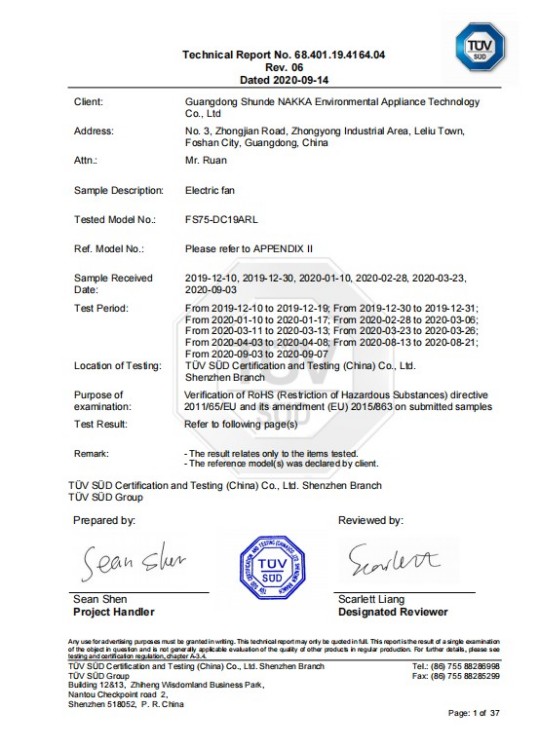

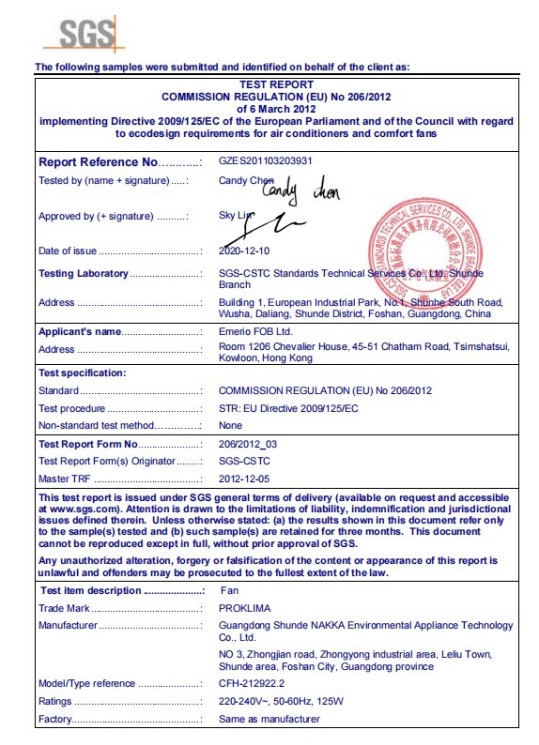

Our Certificate of Inverter Fan and Electric Fan

The Benefits of Inverter Fan

1.Energy-Saving Cooling with Inverter Fans

Inverter fans offer superior energy efficiency by adjusting motor speed according to room temperature. Unlike traditional fans that operate at fixed speeds, inverter fans consume less electricity, resulting in significant energy savings for both homes and businesses.

2.Eco-Friendly Cooling Solution

Inverter fans are an environmentally conscious choice. By using less energy, these fans reduce greenhouse gas emissions and lower your carbon footprint. With inverter technology, you can enjoy optimal cooling while protecting the planet.

3.Save on Electricity Bills with Inverter Fans

Thanks to their energy-saving design, inverter fans consume up to 50% less power than traditional fans. The inverter fans cost only 3KW/H every month.

4.Sustainable and Low Noise Cooling

Inverter fans operate more quietly than standard fans because they don’t need to run at maximum speed all the time. This not only improves comfort but also ensures eco-friendly, noise-free operation, perfect for reducing energy consumption and protecting the environment.

get a free quoteDesign Details of Electric Fan Supplier

Grid Design

- Material: The grid, or cage, that surrounds the blades is typically made of metal, such as steel or aluminum. It protects the blades and motor while also contributing to the fan’s overall aesthetics.

- Design: The grid’s design can influence the fan’s appearance and airflow. Some grids have a more open design to allow for better airflow, while others may have a more closed design for a more compact look.

Base Design

- Stability: The base should be sturdy and stable to prevent the fan from tipping over.

- Adjustability: Some fans have adjustable bases that allow users to tilt the fan to direct airflow as needed.

Controls

- Type: Fans can be controlled using various methods, including mechanical switches, remote controls, and digital controls.

- Features: Some fans offer additional features like timers, sleep modes, and oscillation functions.

Electric Fan Supplier are simple yet essential devices that have undergone significant advancements over the years. Their design and functionality have evolved to cater to various needs and preferences. Here are some key design details to consider:

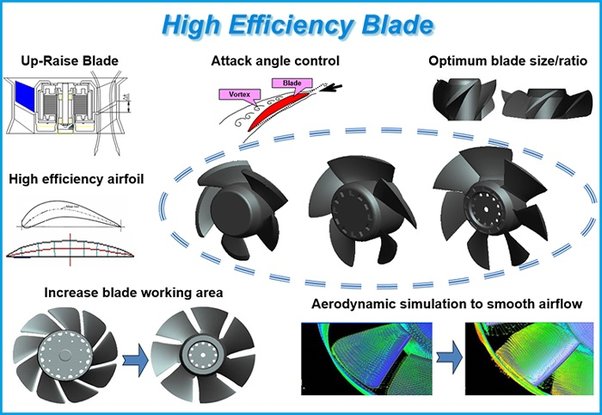

Blade Design

- Shape: Curved blades are most common as they create a more efficient airflow. The curvature helps to accelerate the air, increasing the fan’s effectiveness.

- Number: The number of blades can influence the airflow pattern and noise level. More blades generally provide smoother airflow but may also be louder.

Motor Design

- Type: Most modern fans use brushless DC motors, which are known for their efficiency, quiet operation, and long lifespan. They also offer better speed control compared to traditional AC motors.

- Power: The power rating of the motor determines the fan’s airflow capacity and speed. Higher power ratings are generally used for larger fans or those intended for industrial applications.

The Production Process of Electric Fan

Electric Fan Supplier he production process of electric fans typically involves several stages from design and material selection to assembly and testing. Here’s a general overview:

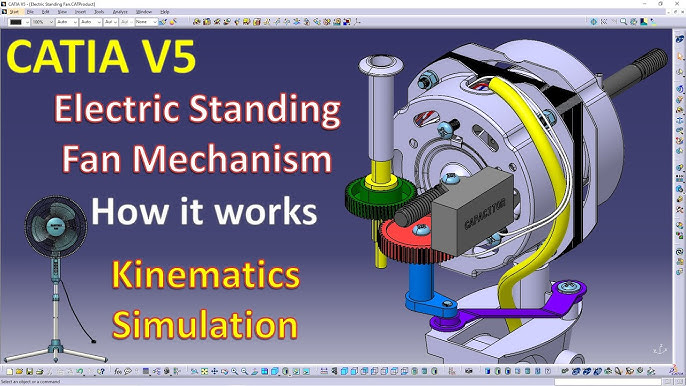

1. Design and Prototyping

– Concept Development: This involves brainstorming and creating a concept for the fan based on its intended use, features, and design aesthetics.

– CAD Modeling: Computer-Aided Design (CAD) software is used to create detailed 3D models of the fan, allowing engineers to simulate airflow, noise levels, and other performance metrics.

– Prototype Creation: A physical prototype is created using rapid prototyping techniques like 3D printing or CNC machining to test the design in real-world conditions.

2. Material Selection

– Blade Material: Blades are usually made from plastic (ABS, PC, etc.), metal (aluminum, copper, etc.), or composite materials depending on the fan’s size, speed, and application.

– Motor: DC motors are common for fans as they offer smooth operation, low noise, and high efficiency. AC motors may be used in some cases.

– Frame and Housing: These can be made from plastic, aluminum, or other durable materials. The choice depends on the fan’s size, weight requirements, and environmental conditions.

3. Manufacturing

– Blade Production: Blades are manufactured using injection molding for plastics or machining for metals.

– Motor Assembly: Motors are assembled with necessary components like capacitors, brushes, and bearings.

– Frame Assembly: Frames and housings are assembled, often involving attaching the motor and blades securely.

– Electrical Components: Wiring, switches, and any additional electrical parts are installed.

4. Quality Control

– Inspection: Each component is inspected for defects and quality issues before assembly.

– Functional Testing: Fans undergo tests to ensure they meet performance specifications, including speed, noise level, and durability.

– Environmental Testing: Fans may be tested under various environmental conditions to ensure reliability.

5. Packaging and Distribution

– Packaging: Fans are carefully packed to protect them during shipping and storage.

– Distribution: Once packaged, fans are shipped to retailers, distributors, or directly to consumers.

Why Choose Us as Electric Fan Supplier

Professional and Advanced Equipment

Electric fan supplier With more than ten years of experience in product manufacturing. Professional technicians provide you with professional advice.

Low Price and High Quality

One stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection and transportation.

Fast and Convenient Delivery

Electric fan supplier fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

Best After-sales Service Provided

Electric fan supplier Improve product sales and technical after-sales service. 24 hours online video call, actively solve problems for customers

What Our Other Customers Say About Us

After-Sales Support

1.Help Desk and Technical Support Services:

2.Real-Time Online Support:

3.Automated Customer Service Lines:

4.Automated Support Resources:

Common Problems With Electric Fan Supplier

Electric fan come in a variety of types, each with its own unique features and benefits. Here are some of the most common types available for selection:

1. Ceiling Fans:

- Designed to be installed on ceilings, ceiling fans provide a wide coverage area and are ideal for large rooms.

- They can be controlled remotely or with a wall switch.

- Some ceiling fans have built-in lights for added functionality.

2. Stand Fans:

- Portable fans that stand on a base, stand fans are versatile and can be easily moved from room to room.

- They come in various sizes and styles, from small desk fans to larger floor fans.

- Many stand fans offer adjustable height and tilt features.

3. Pedestal Fans:

- Similar to stand fans, pedestal fans have a tall, slender design that allows for better airflow.

- They are often used in larger spaces or areas with high ceilings.

4. electric fan supplier:

- Compact and powerful, electric fan supplier are typically used for industrial or commercial applications.

- They are often used for ventilation, air circulation, and cooling large spaces.

5. Clip-On Fans:

- Small, portable fans that can be clipped onto surfaces like desks, shelves, or beds.

- Clip-on fans are ideal for personal use and can be easily moved around.

6. USB Fans:

- Powered by a USB port, these small fans are perfect for use with laptops, computers, or power banks.

- They are often used for personal cooling or for cooling electronic devices.

7. Tower Fans:

- Sleek and modern, tower fans have a tall, narrow design that takes up minimal space.

- They are often used in bedrooms or living rooms and offer quiet operation.

8. Misting Fans:

- Combine the cooling effects of a fan with the refreshing mist of water.

- Misting fans are ideal for outdoor use on hot days and can help to reduce humidity.

9. Industrial Fans:

- Large, powerful fans designed for industrial or commercial applications.

- Industrial fans are used for ventilation, air circulation, and cooling large spaces.

Electric fans are typically made from a combination of materials, including:

Motor:

- Stator: Made from laminated steel or silicon steel.

- Rotor: Made from copper wire wound around a steel core.

- Magnets: Made from rare earth magnets, such as neodymium magnets.

Blades:

- Plastic: ABS, polypropylene, or nylon are commonly used for blades.

- Metal: Aluminum or steel can be used for blades, especially in industrial fans.

Grid:

- Metal: Steel or aluminum is typically used for the grid that surrounds the blades.

Base:

- Plastic: ABS or polypropylene are common materials for bases.

- Metal: Steel or aluminum can be used for bases, especially in larger fans.

Controls:

- Plastic: ABS or polypropylene are used for control buttons and housings.

- Electronics: Printed circuit boards, resistors, capacitors, and other electronic components are used in the controls.

Other Materials:

- Wiring: Copper wire is used for electrical connections.

- Bearings: Ball bearings or sleeve bearings are used in the motor.

- Screws and Bolts: Stainless steel or galvanized steel screws and bolts are used to assemble the fan.

The standard size of electric fans can vary depending on the type of fan and its intended use.

Here are some general size ranges for common types of electric fan supplier:

- Ceiling Fans: Typically have blade spans ranging from 36 to 72 inches (91 to 183 cm).

- Stand Fans: Can vary greatly in size, but common blade diameters range from 12 to 20 inches (30 to 51 cm).

- Pedestal Fans: Similar to stand fans, with blade diameters typically ranging from 12 to 20 inches.

- Box Fans: Usually have blade diameters around 12 to 16 inches (30 to 41 cm).

- Clip-On Fans: Typically have blade diameters around 6 to 8 inches (15 to 20 cm).

- USB Fans: Often have smaller blade diameters, around 3 to 5 inches (7.6 to 12.7 cm).

- Tower Fans: Can vary in height, but typically have blade diameters around 10 to 12 inches (25 to 30 cm).

Yes,our electric fan supplier can provide customized sizes for electric fans. This is especially common for industrial or commercial applications where specific requirements may need to be met.